Search no more. You found the information in regard to performance upgrade for BMW M60 hydraulic lifters. They are also known as flat tappets, hydraulic tappets or just simply – lifters – they are all meaning the same – a hydraulic element which is in between your engine’s camshaft and valve, adjusting the valve clearance by utilizing hydraulic pressure. They are called flat tappets for a reason: the top of the lifter is flat, and while its moving up and down in relation to an engine speed, it is also rotating around its axis. Inadequate manufacturing quality (When using cheap Chinese parts) and the requirement for flat tappet rotation can create major challenges during a first startup, if lifter(s) will fail to rotate. This can lead to permanent cylinder head and camshaft damage.

Engine comparison: M60 vs. M62 engine

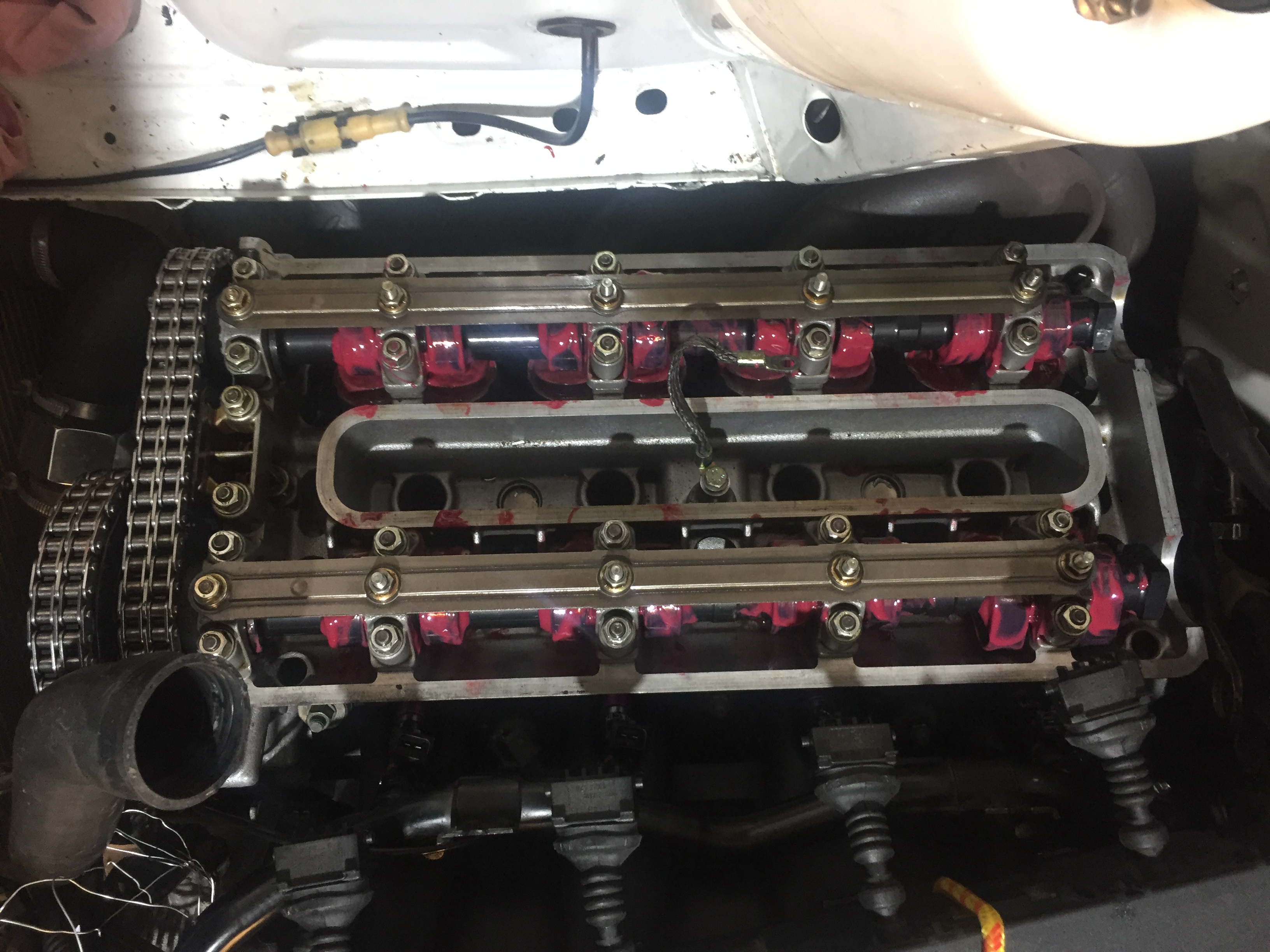

M60 engine design is from early 1990’s. This means the engine was utilizing 35mm valve lifters used in both M50 and M42 engines. On M62, the factory wanted to reduce:

A) Rotating masses,

B) Increase the total efficiency of the engine,

C) Make the engine more quiet and sophisticated,

D) Reduce manufacturing costs

Thus the reason, why the factory ended up upgrading flat tappets on M62 to smaller diameter of 33mm. From the perspective of performance tuning, some of M62 modifications are not welcomed in terms of top rpm reliability, like the infamous change from “stronger-than-a-tank” duplex timing chain to a fragile single version. OK, let’s get back to lifters.

According to bmwfans.info, M60 hydraulic valve lifters weigh 78 grams,

While M62 flat tappets weigh only 52 grams, according the same source.

Please note: that is over 26 grams weigh reduction per valve-spring package! When you multiply that by 32, you can see, how the factory managed to save 832 grams from the flat tappets only!

Benefits of utilizing the lighter valve train on M60 engine

Because heavier M60 flat tappets require more stiffer valve springs, M60 engines have dual valve springs, while M62 has single ones. In terms of performance tuning, this can be either disadvantage, or advantage. The upside is: if you can find a way to reduce the overall weight of moving masses from M60 valve-spring package – without affecting the spring rates, you can get your valve train to sustain higher rpm range. And this is especially advantageous if you are after naturally aspirated performance tuning.

Our calculations show, that by reducing 20 grams from the valve-spring package – while utilizing both M60 stock valve springs – your M60 engine can sustain revs up to 8400 rpm. Ladies and gentlemen: it is on S65 territory!

Do I have to change my cylinder heads to M62?

No. You do not have to change your cylinder heads to M62, if you own M60 engine. Actually, the reality is the other way around: you may be interested in creating so called hybrid or frankenmotor with M62 bottom end matched to M60 cylinderheads – this will provide you prerequisites (Prerequisites only, thus most frankenmotor projects I have seen have failed to utilize this untapped potential) to build a high compression performance engine.

If you already have M62 engine, the advantage of hybrid motor is the upgrade to more robust duplex timing chain. The end result is pretty neat way to combine the best features from both engine families. Only downside is the heavier M60 valve lifters.

How to fix the issue of heavy flat tappets on M60 engine?

This modification is applicable if you are:

A) After performance upgrades,

B) Not worried about engine sophistication nor quietness,

C) Chasing for reliability on 7000rpm + category

You may have heard stories about fitting VW lifters to M42 318is engine, but you are lacking the proof of concept, right? Afterall, both M42 and M60 are using the same flat tappets.

Here is the proof of concept: I have successfully drove the M60 engine with VW tappets over 12 000 kilometers. Yes, they are not the most quiet, but they can take up the beating. My rev limiter was initially set to 7800 rpm. Afterwards, it was lowered to 7600 rpm. That is essentially the effective shift point in lower gears.

VW hydraulic lifters to BMW M60 engine

The VW valve lifters in question are manufactured by Febi Bilsein. They can be any brand you prefer. I ordered mine from autodoc.de – not the best service, but affordable prices.

The part number is 07060,

outer diameter 35 mm

Height: 26mm.

Weight: 56 grams

Happy E30V8 revving!

I am about to start this build.

LikeLike

I’m about to build a m60b46 using the information im learning from this blog. Can I use m60 valve springs with vw lifters for upgraded cams with higher valve lift? Oem is 9.7/9.4mm where as cat cams go as far as 11/10mm.

LikeLike

Just follow the remarks from Cat Cams website for a cam type you are about to install, and you are good to go.

LikeLike