Please read “Why to build custom 4,4 litres BMW M60B44 engine?” before proceeding with this article since the former is describing the prerequisites for a high performance M60B44 build.

For starters – Internal Combustion (IC) engine is an air pump

Naturally aspirated engine tuning is plain simple: (yet so ever challenging!)

A) Think your engine as an air pump,

B) Air is always moving from higher pressure to lower.

In order to increase the amount of air your naturally aspirated engine can transfer, you can:

1) Increase the size of an air pump (cc, cid),

2) Increase the effective speed of an air pump (rpm),

3) Optimize the gasdynamics for desired rpm band, such as matching cams and pressure waves with both intake and exhaust systems for optimal volumetric efficiency and scavenging effect,

4) Increase the intake air density with cooler air temperature,

5) Reduce pressure losses in the intake air path to minimum.

The Foundation of Naturally Aspirated engine: Displacement

Actually this applies for forced induction engines too. The very base foundation for HP/Torque capability is the engine displacement. Even in turbocharged applications, there is no replacement for displacement. More is better, until you hit the maximum tolerated piston speed.

Bore and stroke:

S65B40 engine with 4,0 litres has 92 mm x 75.2 mm (Bore x Stroke),

M60B40 engine with 4,0 litres has 89 mm x 80 mm (Bore x Stroke),

M62B44 engine with 4,4 litres has 92mm x 82,7mm (Bore x Stroke),

S62B50 engine with 5,0 litres has 94 mm x 89 mm (Bore x Stroke).

For comparison, Ferrari 458 engine with 4,5 litres has 94mm x 81mm (Bore x Stroke),

Rod to stroke ratios:

S65B40: 140,7mm : 75,2mm = 1,87

M60B40: 143mm : 80mm = 1,79

M62B44: 143mm : 82,7mm = 1,73

S62B50: 141,5mm : 89mm = 1,59

Mean piston speeds:

S65B40: 21 m/s @8400rpm

M60B40: 21 m/s @7850rpm

M62B44: 21 m/s @7600rpm

S62B50: 21 m/s @7000rpm

RULE 1: In naturally aspirated engine, an engine displacement will give you torque characteristics for low-to-mid rpm range. The maximum torque you can achieve is approx. 120nm per litre on NA-engine.

RULE 2: Stroke will dictate maximum tolerated piston speed, and bore how big valves you can use. Shorter stroke means less piston speed and higher revving engine – but less torque on low end.

Read on, and learn the RULE 3 below.

Maximum torque per litre, naturally aspirated engines

80 nm/l: stock 2-valve NA-engines

100nm/l: Best 2-valve NA-engines

100-110 nm/l: Modern, stock 4-valve NA-engines

110-120 nm/l The best stock, and modified 4-valve NA-engines

The character of naturally aspirated engine: Cams

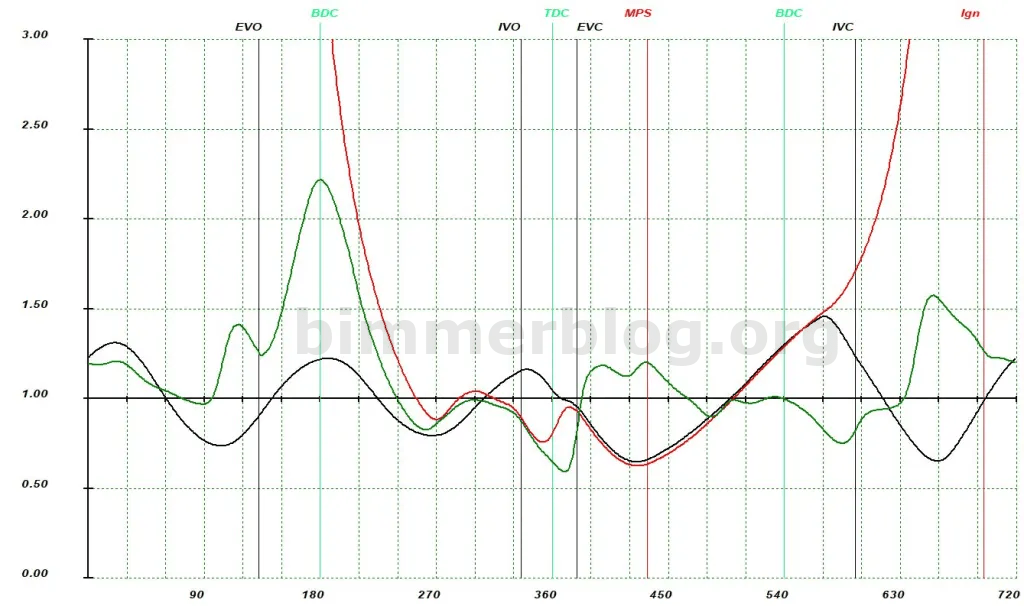

“Why hotter cams 101”: If you seek for more power, you have to increase volumetric efficiency of an engine, and/or stretch the power band towards higher rpm range.

When you rev higher, the following will happen:

A) Less and less time your engine valves stays open (in milliseconds) in relation to rpm.

And;

B) Flowing gasses create more and more inertia, and fluid friction.

Take home points:

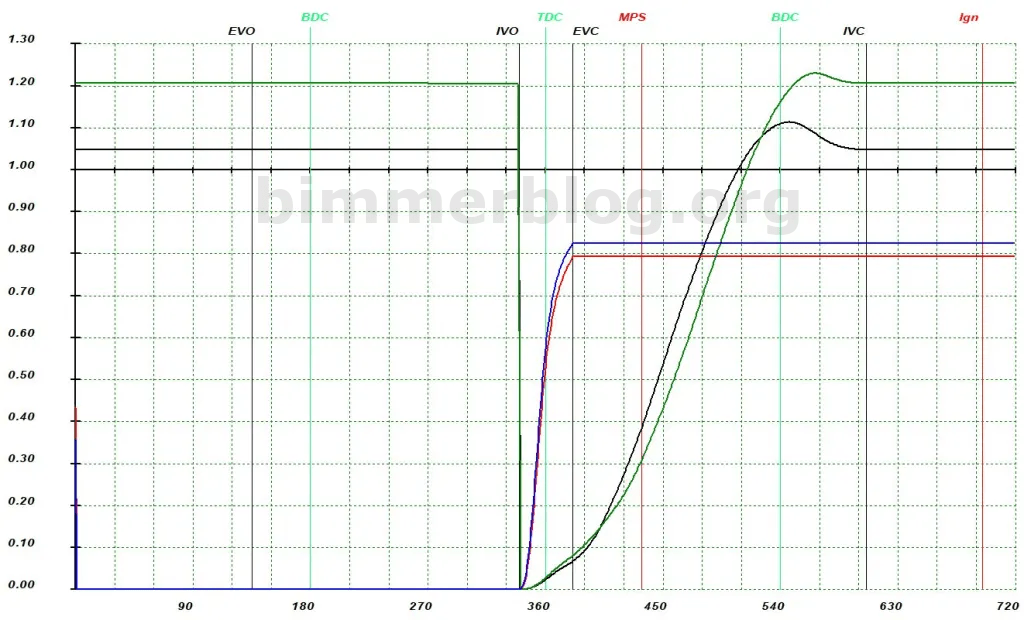

Problem A) can be tackled by assembling higher degree cams. This enable valves to stay open longer (in milliseconds) on higher rpm range.

Problem B) Increased overlap paired with good exhaust headers can take advantage of increased gas inertia. Exiting exhaust gasses in the header are creating both positive and negative pressure pulses, which can create low pressure areas, thus creating ‘scavenging effect’. OK, let’s explain this in the other words: While gasses are always looking for a route from higher pressure area to lower, during scavenging effect exhaust gasses have enough kinetic energy to keep moving forward – which in ideal situations – can create low pressure area around exhaust valve and combustion chamber during intake opening. This pressure differential can assist combustion chamber to empty burnt gasses more efficiently, while simultaneously sucking fresh air from induction system. This is called scavenging effect, and can improve your engine’s Volumetric Efficiency (VE), and produce more torque on desired rpm range. This is why you have to choose in between primary lengths for either optimal low-to-mid range torque, or maximum top end power. A note: 42mm OD primaries are fine up to 600hp!

RULE 3: In naturally aspirated engine, cylinder head flow capability in relation to engine size (cc, cid) will dictate torque characteristics for desired (Such as upper) rpm range. Number of valves, valve sizes, head porting, cam geometry – these all have an affect on volumetric efficiency(VE) for your desired rev range.

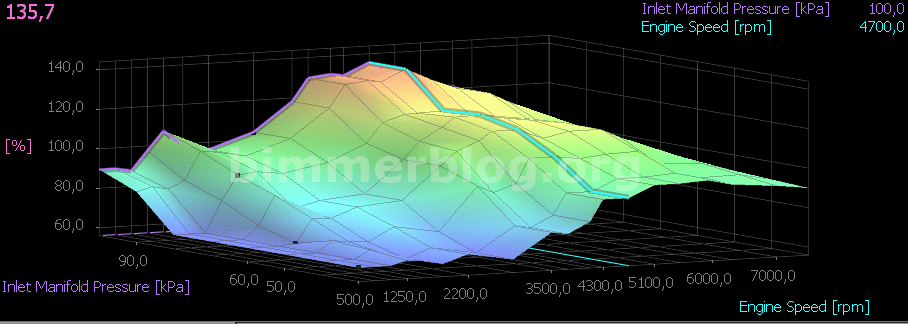

Scavenging efficiency and delivery ratio of intake system

Scavenging effect – also known as reverse or negative supercharging – is typically combined with inertial, or inertia supercharging, which in short can utilize A) kinetic energy of incoming air, and B) acoustic supercharging (rebounding resonances) in between a closing intake valve and intake manifold plenum. Model year 1992 intake manifold with proper velocity stacks has potential to high delivery ratio (DRatio) on mid range. The advantage over short ITBs can be up to 65nm on 4500rpm.

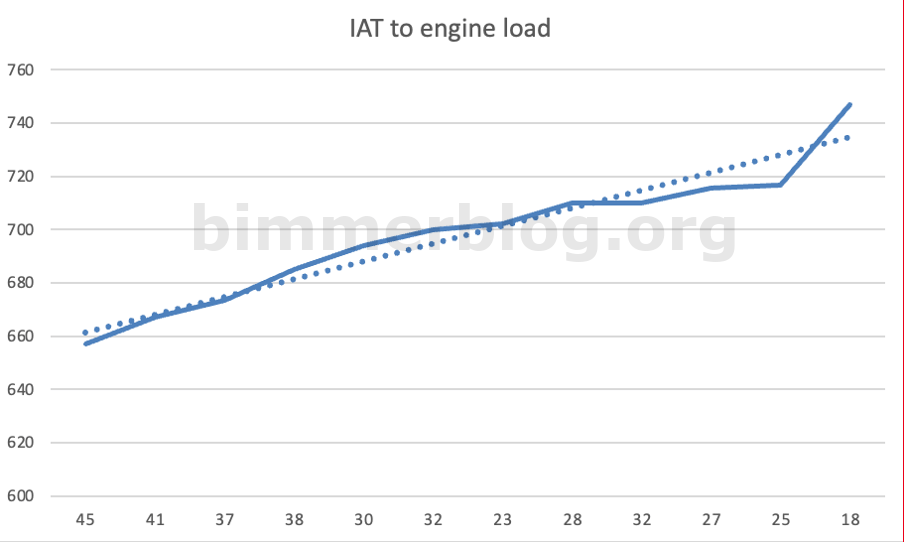

Improving intake air density by eliminating the causes of heat soak

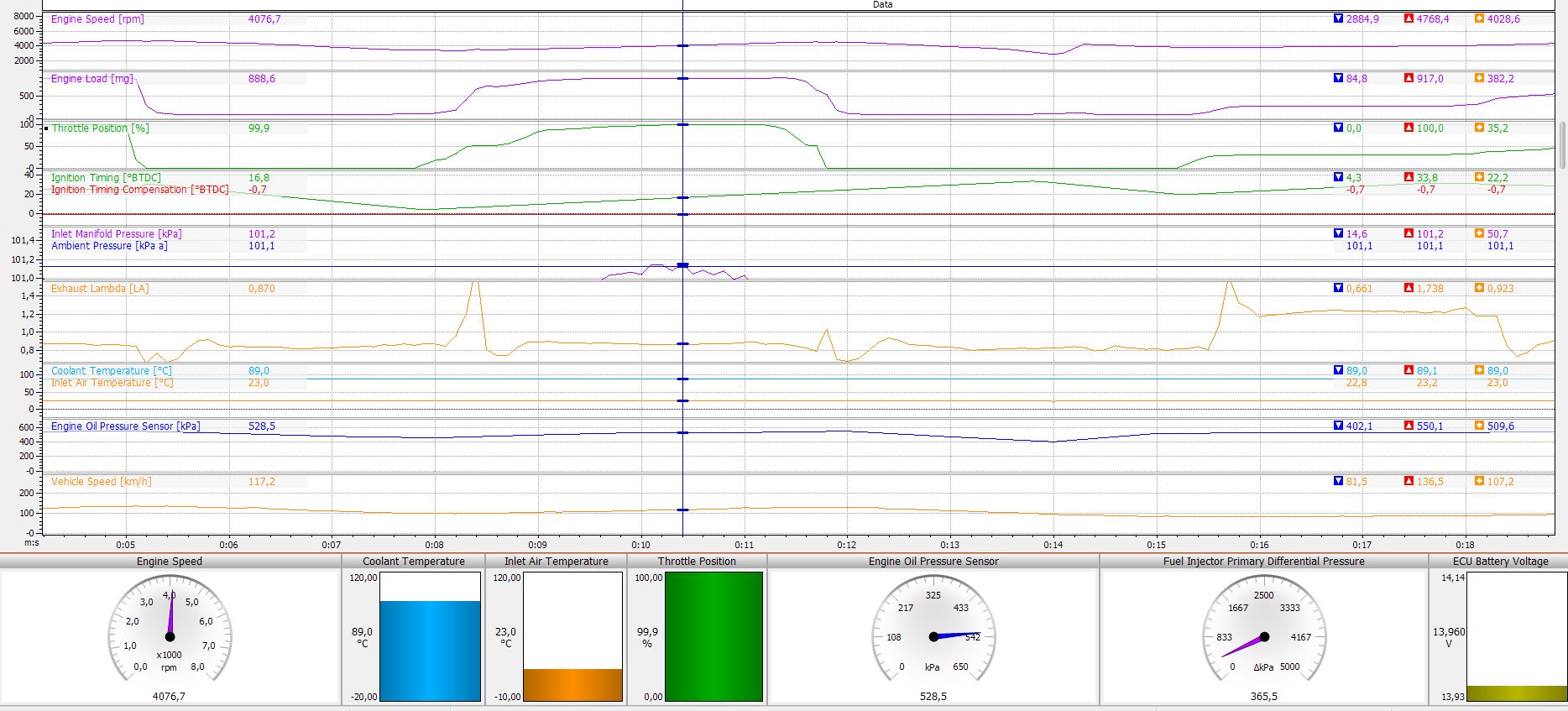

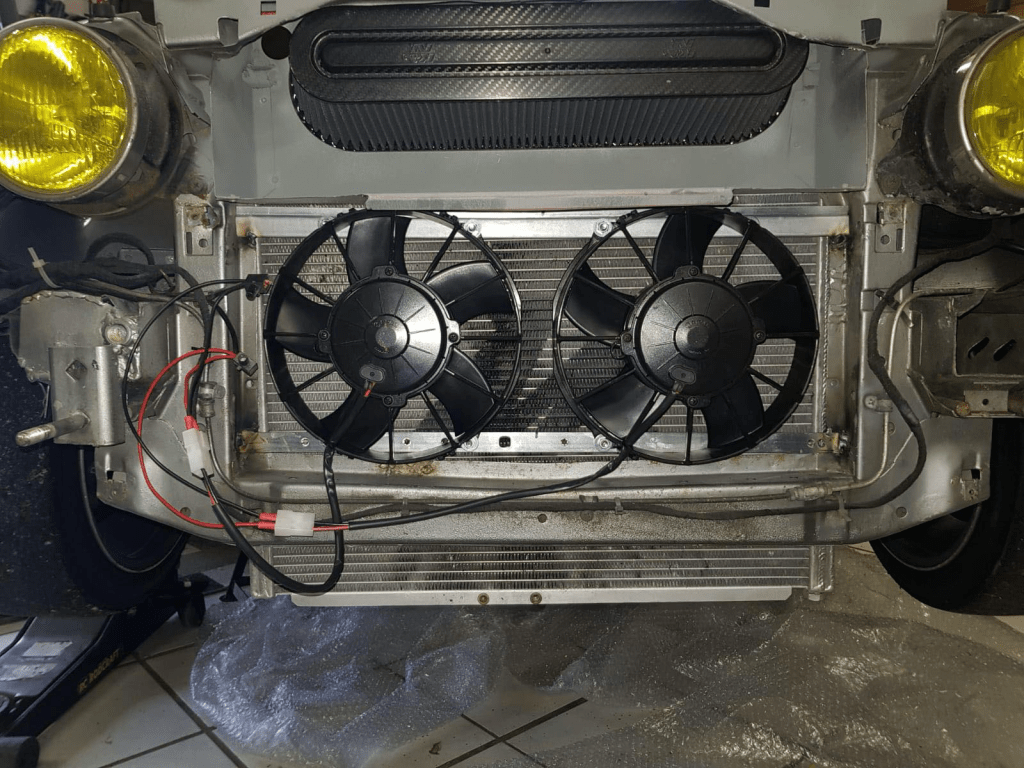

NOTE TO SELF: DIN corrected, dyno verified torque on my M60B44 engine is 113 nm per litre, measured on highly respectable hub dynamometer with DIN correction, and known for its accuracy. On street, under optimal conditions with +7 C outside temperature, the log data has shown engine loads as high as 119,4nm per litre. Please note this is NOT torque by DIN standard, only peak calculated torque from maximal engine load, hardly comparable with any other engines than my own. The difference in between dyno vs street is also due to fact the engine has very high dynamic compression, so it is(or was) suffering from heat soak while being stationary. During the dyno run the stock Intake Air Temperature (IAT) was showing temperatures up to 110 Celsius. While driving on street IAT sensor is showing +8C on top of ambient temperature, meaning IAT of 28C on street means +20C ambient temperature. The delta for inlet system temperature was staggering 82C on dyno. Since DIN corrections are based on atmospheric temperature, corrections are not taking account of temporary heat soak in the engine. The delta in inlet wall temperature was later analyzed and showing 3.8% loss in engine torque. The heat soak issue was eventually solved with less aggressive idle ignition management, combined with improved intake manifold insulation and engine cooling methodologies. The difference is not only calculative, its seat-of-the-pants noticeable on a hot summer day.

Reducing pressure losses in the intake manifold

Higher intake manifold pressure than atmospheric pressure on naturally aspirated engine is rare sports. The pressure loss in the intake plenum can be minimized with RAM-air effect. There was 2 kPa pressure delta in intake manifold during the one mile run. This is not much, but states the RAM-air system works. When compared to filter on hot side, the benefit of RAM-air intake can more than 4 kPa. This kinda pressure loss is a no go for high performance, naturally aspirated engine, since they operate with such small pressure differential. MAP sensor is located at the end of intake manifold plenum. Although that being said, this data does not prove – nor deny – the existence of inertial supercharging, which can happen closer to an intake valve where incoming air can be compressed. As we learned earlier, the delivery ratio can be over 1.20 when both exhaust and intake systems are matched together, and optimized.

Examples of air intake optimizations:

Air intake on hot side, 100kPa Ambient

Air intake on hot side, 98kPa on WOT

RAM-air intake, 100kPa Ambient

RAM-air intake, 102kPa on high speed WOT

___________________

= The pressure loss (or save!) can be up to 4kPa

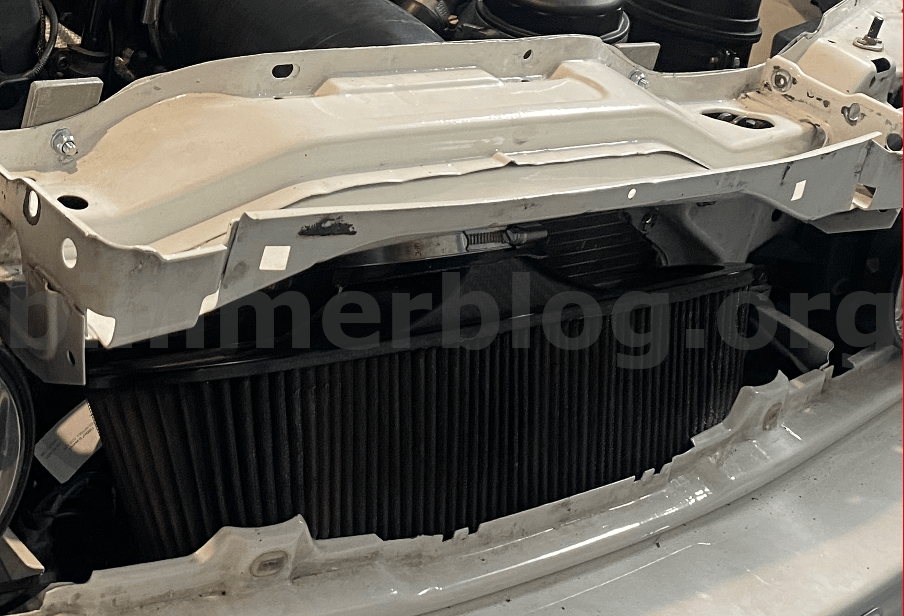

The Cold Air Intake (CAI) with RAM-air effect the market doesn’t sell

Let’s be clear: The majority of aftermarket Cold Air Intakes (CAI) do not work. They are just cool looking parts sucking hot and low pressure air under the bonnet. This is especially bad for naturally aspirated engines as stated in the previous paragraph. The filter you can use is K&N part nr. 63-3052. You can use other C6 Corvette filters too. The log data from one mile runs verifies the existence, and efficiency of the RAM-air system below.

About the importance of data logging and measuring

I have tested different optimization techniques based on the principles presented in this article. The baseline is initial dynorun. Mg/stroke is the engine load (Torque). The difference in engine output at 6900 rpm can be over 10% when optimizing both intake and exhaust systems. The most visible modification is Corvette style CAI with RAM-air effect. Other modifications are not visible. 7,4% difference was measured during one mile run with RAM air effect (+18C ambient temperature), and 10,4% difference with cold weather (+7C ambient temperature). Thereafter more optimizations have been implemented. The data point of 6900 rpm was selected simply by the availability of data, and due to interest in optimizing torque on upper rev range – without sacrificing low-to-mid end torque. These optimizations have made huge difference, and unlocked full potential of the engine. Fast forward to today, and possible modifications are being analyzed in advance. This can save a lot of time, money, and from disappointment.

More information about performance upgrades can be found on my other articles: